Materials

environmentaly friendly

The innovative packaging of tomorrow, it is what we will design together .

Each product has its own process. Packaging specialists and aware of the environmental issues linked to packaging, we work daily on the development of new solutions in partnership with various players. From these different collaborations were born different packaging that is ecological, greener and more innovative.

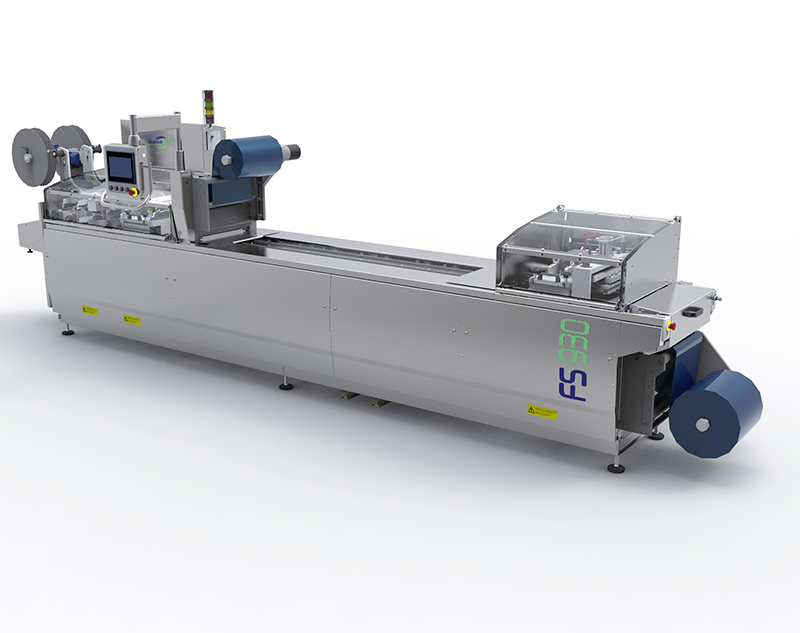

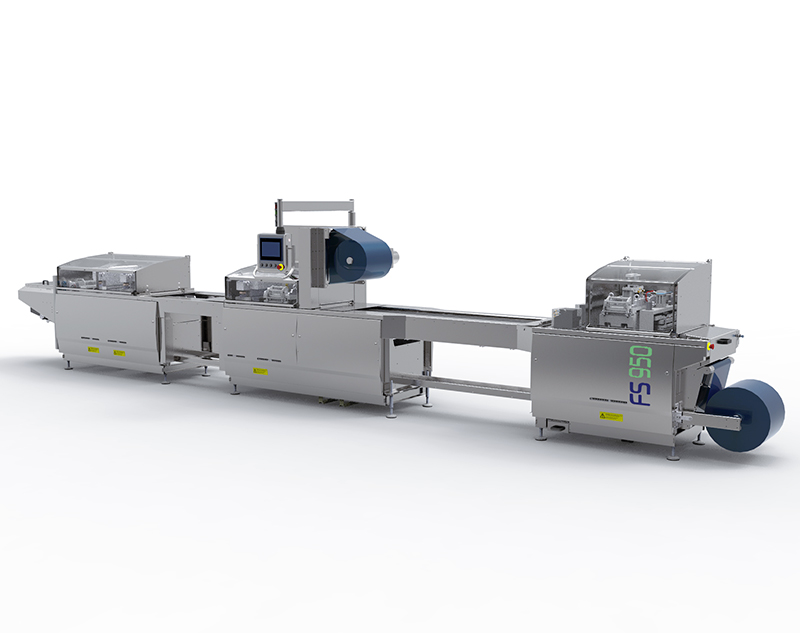

It is possible to work with trays thermoformed by our machines, in various eco-responsible materials thanks to bio-based, biodegradable, single-material and recyclable films (eg PP or simple PET) with thermoforming carried out by blowing, vacuum or pistoning.

Find out more about our CSR approach